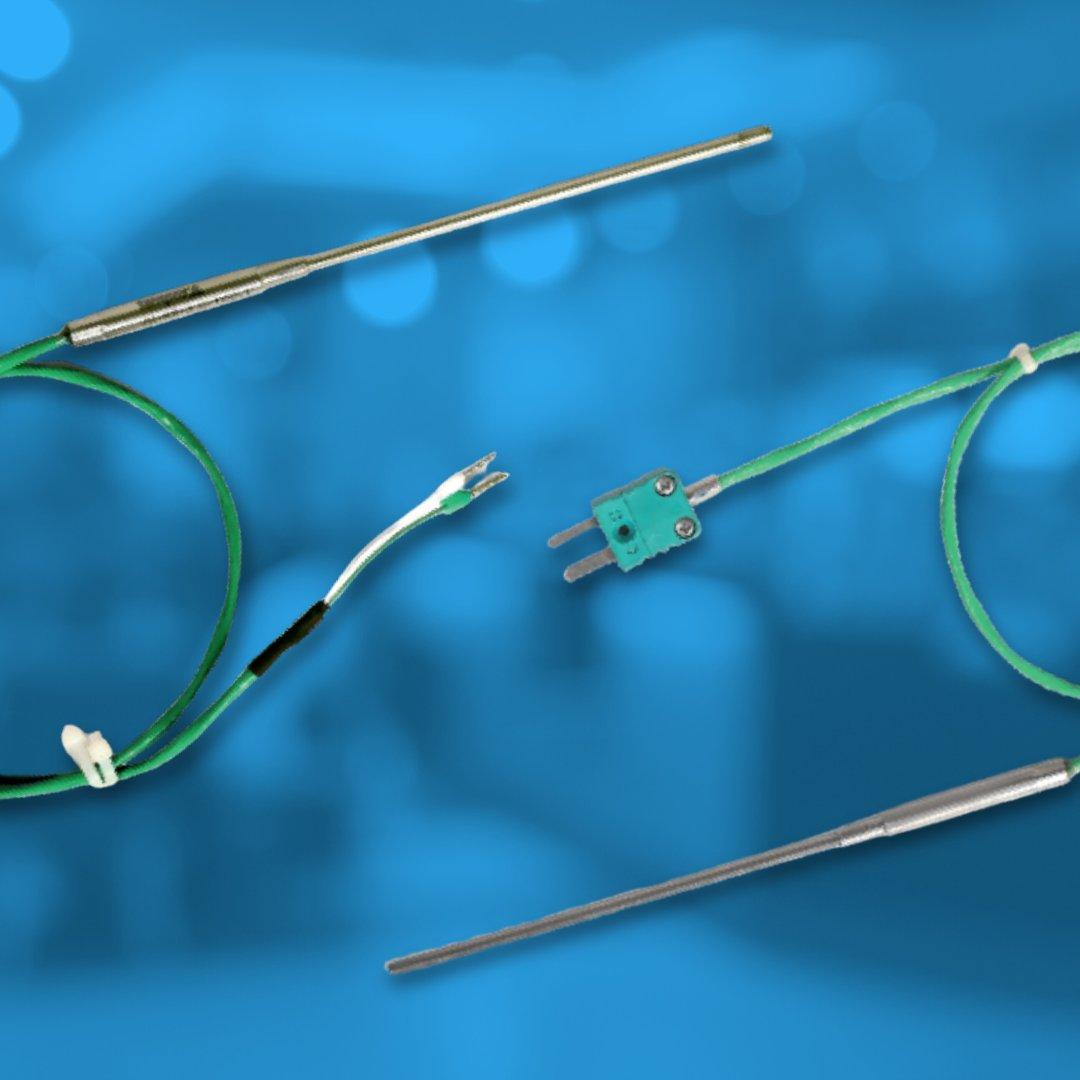

(AL, ALSTE, STE type thermocouples)

Type: J, K, T, E, N

Element Size (MI): 0.25, 0.5, 1, 1.5, 1.6, 3, 4.5, 4.8, 6, 8, 10 (mm). Other Sizes on request.

Protection Sheath: SS321, SS316, SS310, INCONEL 600, 601, Platinum, Pyrosil, Nimonic, HRS 446, Molybdenum etc.

Configuration: Simplex/Duplex/Multipoint.

Special: As per ASTM E235 for nuclear application.

Type: J, K, T, E, N, R, S, B

Element Size (MI): 0.25, 0.5, 1, 1.5, 3 (mm). Other Sizes on request.

Protection Sheath: SS316, SS310, INCONEL 600, Pyrosil, Nimonic, Molybdenum etc.

Configuration: Simplex/Duplex/Multipoint, (other size on request)

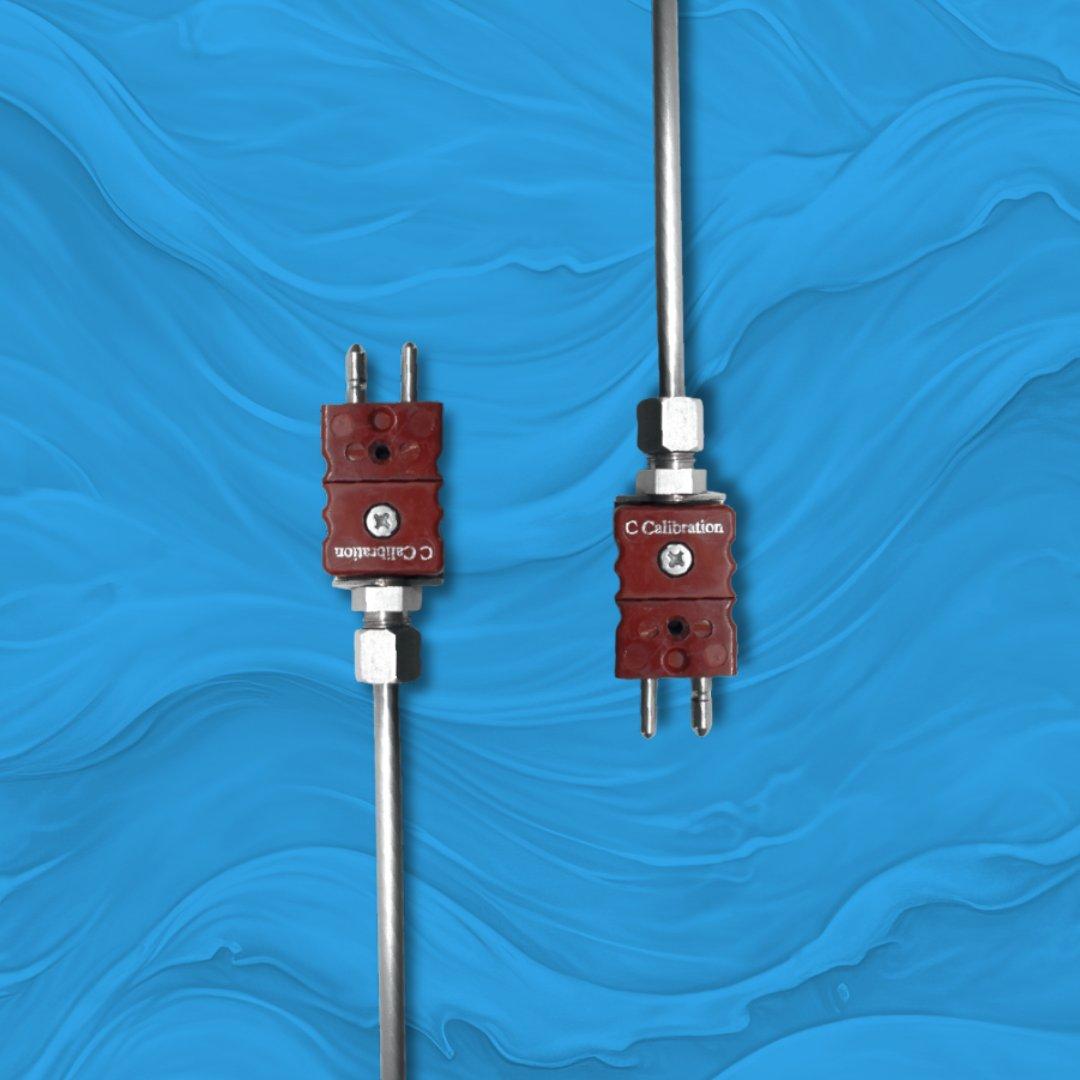

Type: J, K, T, E, N

Element Size (MI): 0.25, 0.5, 0.75, 1, 1.5, 2.3, 4.5, 6, 8 (mm). Other Sizes on request.

(Non-MI): 1.6, 2, 2.5, 3.2 (mm). Other Sizes on request.

Protection Sheath: SS304, SS321, SS316, SS310 HRS 446, INCONEL 600/601/800, Nickel, Hastalloy, Titanium, Tantalum, Ceramic 610 & C-799, Silicon Carbide, Monel, Nimonic, Molybdenum etc.

Configuration: Simplex/Duplex/Multipoint

Application: Cement, Chemical, Process, Furnace industry, Aerospace, Automotive Industry, Forging, Refrigeration, Power Plant, Mining, Petro Chemical

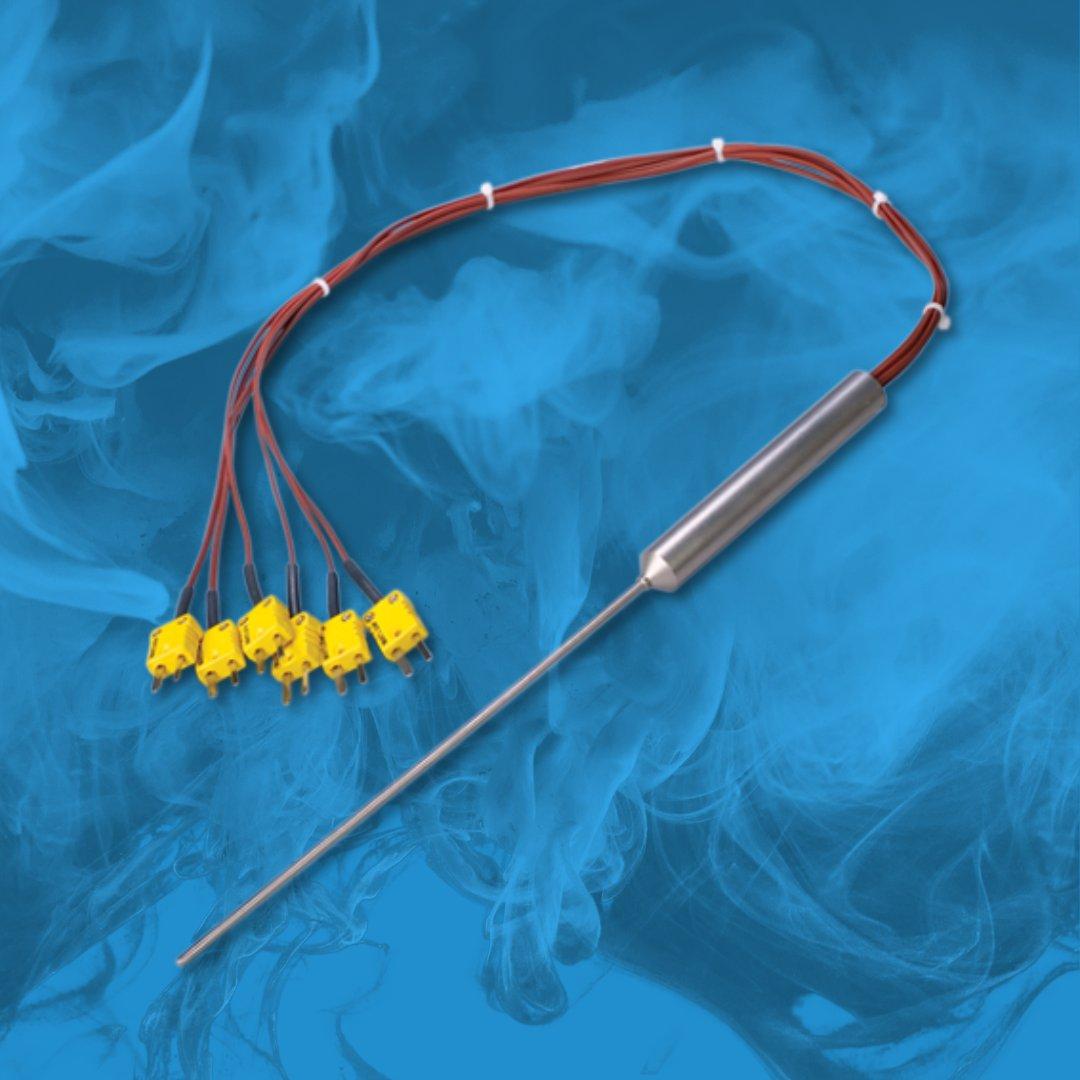

A multi-point thermocouple is a temperature-sensing device that measures temperatures at multiple points or locations. It consists of multiple thermocouple junctions connected to a single wire or cable.

Type: S, R, B & C (operating temperature up to 2300°C)

Sheath Material: Platinum, Rhodium, Tantalum, Rhenium, Molybdenum, Inconel 600, Ceramic etc.

Transition Sleeve: SS316 or INCONEL

Insulation Material: Magnesium Oxide, Aluminium Oxide, Beryllium Oxide, Hafnium Oxide

Large range of thermocouples designed to measure temperatures up to 1,200°C directly at its warehouse. Available options include thermocouples with insulation made from fluoroplastics FEP, PFA and PTFE as well as thermocouples insulated with the polyamide material Kapton or glass fibre and ceramic materials.

Skin type thermocouples are available with various head types to suit different applications and surfaces. Here are some common head types:

When selecting a skin type thermocouple head type, consider factors like:

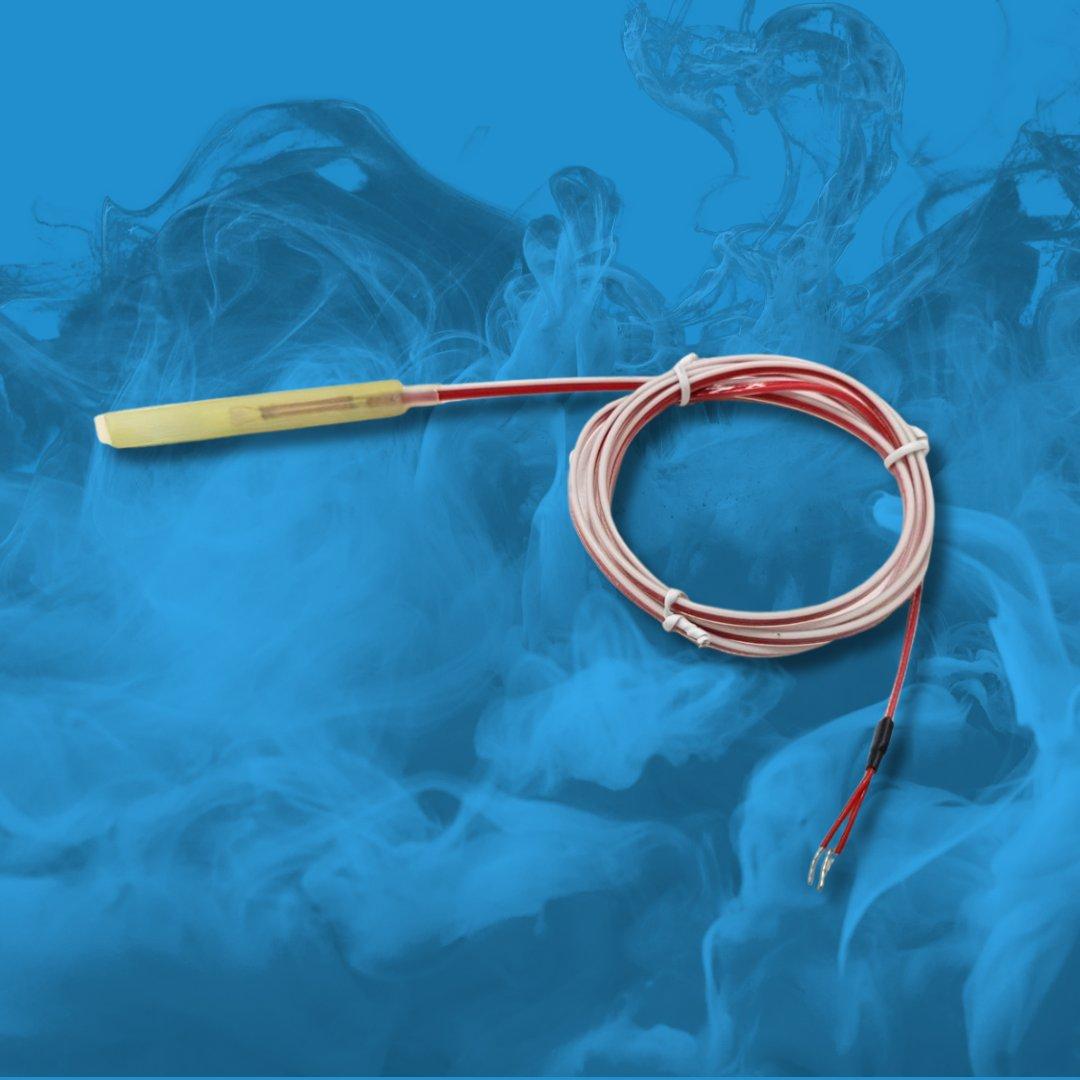

A weld pad thermocouple is a type of thermocouple designed for temperature measurement on surfaces, particularly in welding applications. It consists of a thermocouple junction attached to a flat, flexible pad.

Large range of thermocouples designed to measure temperatures up to 1,200°C directly at its warehouse. Available options include thermocouples with insulation made from fluoroplastics FEP, PFA, and PTFE as well as thermocouples insulated with the polyamide material Kapton or glass fibre and ceramic materials.

Type: J, K, T, E, N

Element Size (MI): 0.25, 0.5, 0.75, 1, 1.5, 2.3, 4.5, 6, 8 (mm). Other Sizes on request.

(Non-MI): 1.6, 2, 2.5, 3.2 (mm). Other Sizes on request.

Protection Sheath: SS304, SS321, SS316, SS310 HRS 446, INCONEL 600/601/800, Nickel, Hastalloy, Titanium, Tantalum, Ceramic 610 & C-799, Silicon Carbide, Monel, Nimonic, Molybdenum etc.

Configuration: Simplex/Duplex/Multipoint

Application: Cement, Chemical, Process, Furnace industry, Aerospace, Automotive Industry, Forging, Refrigeration, Power Plant, Mining, Petro Chemical

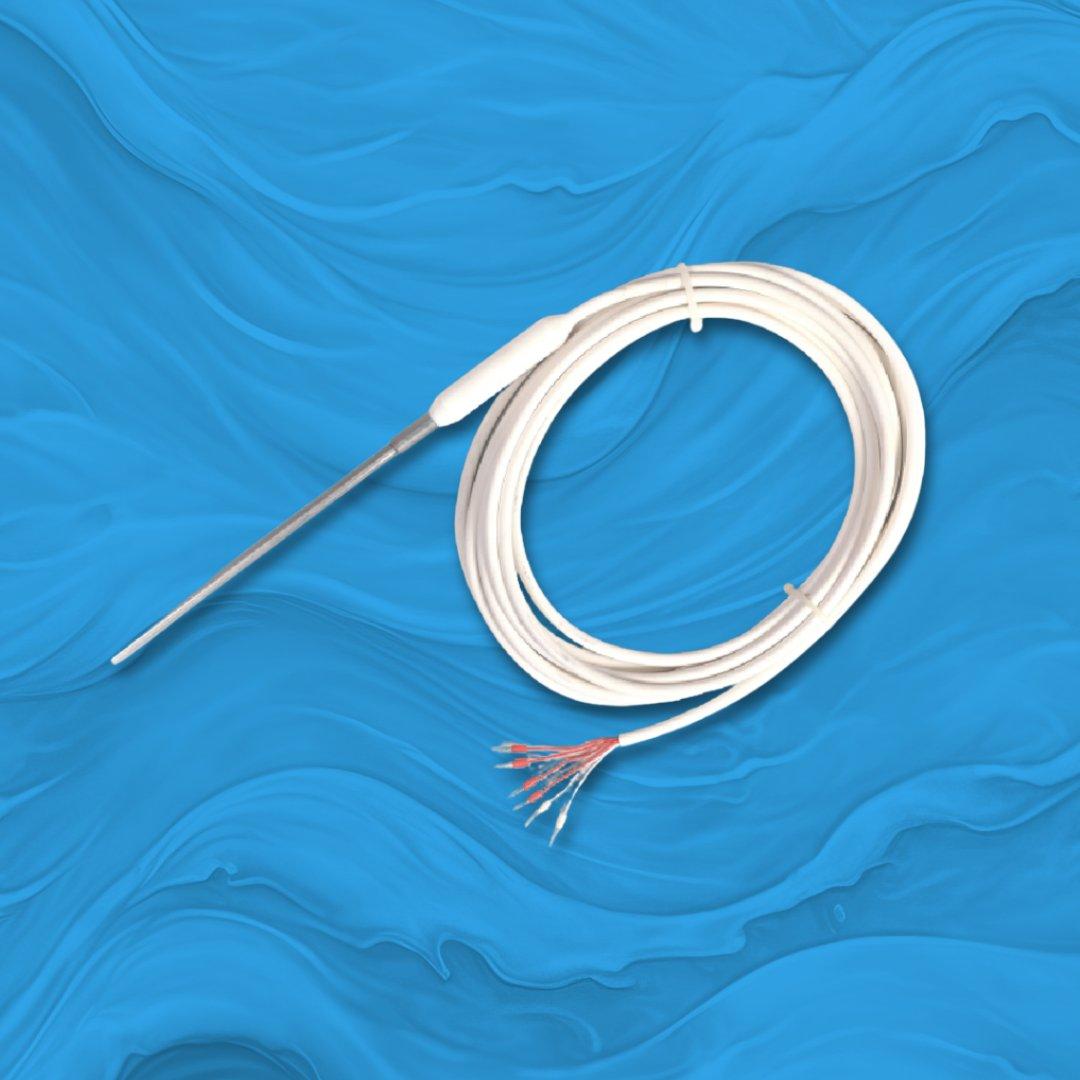

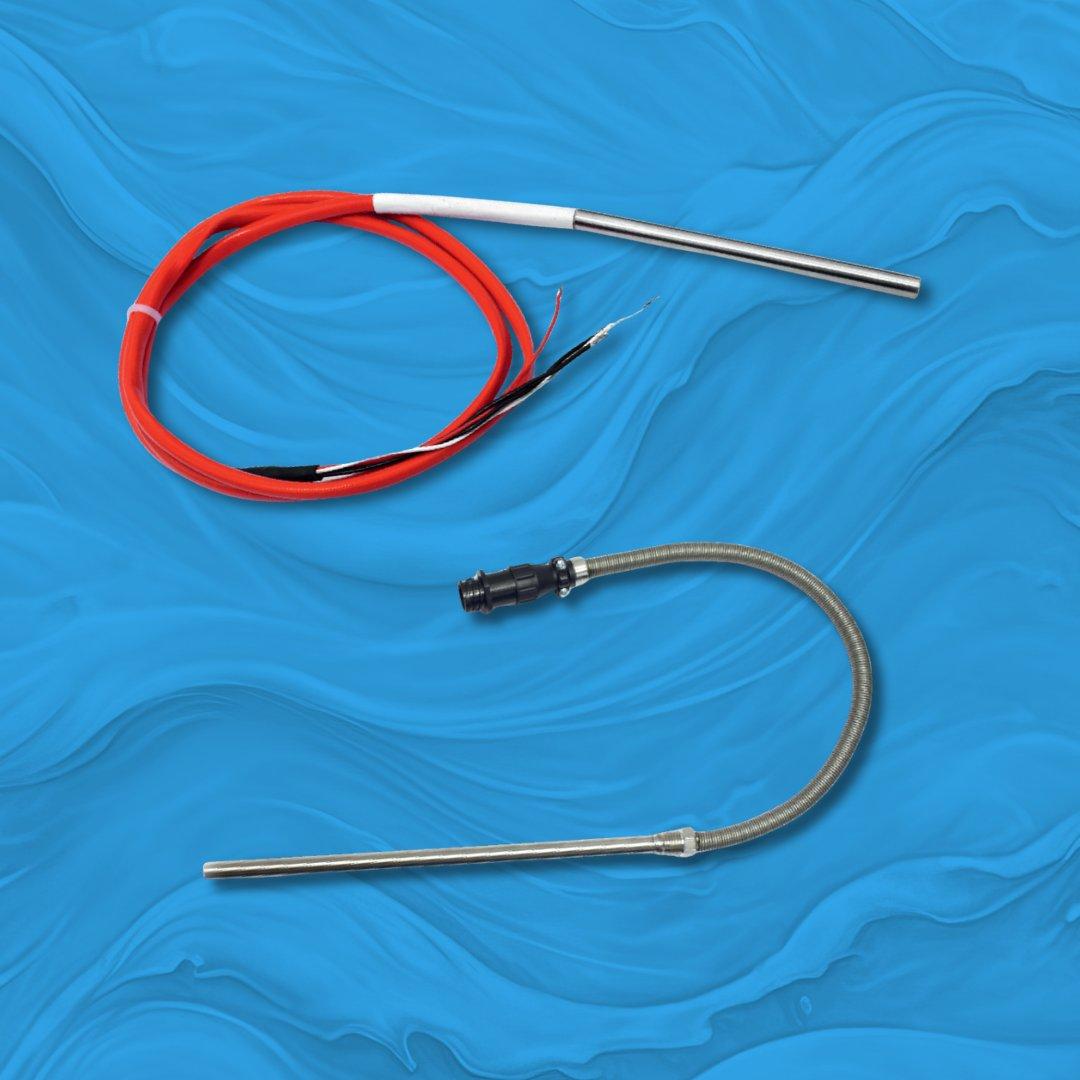

Type: Pt 100, 200, 500, 1000, Cu-50, Cu-53 etc.

Connection: 2, 3, 4 wire

Element Diameter: 1.5, 2, 3, 4, 4.8, 6, 8 mm (Other sizes on request)

Configuration: Simplex / Duplex / Others

Due to their small diameter, they offer very short response times and are suitable for hard-to-reach, winding spots and narrow openings. Sheathed resistance thermometers are ideal for temperature monitoring and process control, capable of measuring thermal conditions in gaseous and liquid media, on solid surfaces, as well as in tanks, pipes, apparatus, and machines. Rapid response times at diameters < 1.5 mm.

Tube type RTDs are designed for precise temperature measurement in liquid and gaseous media at temperatures ranging from -200°C to +600°C, and in exceptional cases, up to +850°C.

Connection: 2, 3, 4 wire

Element Diameter: 1.5, 2, 3, 4, 4.8, 6, 8 mm (Other sizes on request)

Application: Automotive test bench, process, furnace, pharmaceutical industry, etc.

These RTDs are designed for precise temperature measurement and protection in challenging environments. They feature thermowells or protection tubes for durability and safety during industrial processes.

Type: Pt 100, 200, 500, 1000, etc.

Element Size (MI): Wire wound ceramic encapsulated, Wire wound glass encapsulated, Thin film ceramic encapsulated

Connection: 2, 3, 4 wire

Accuracy: Class A, B, 1/2, 1/3, 1/5, 1/10 DIN

Protection Sheath: SS304, SS321, SS316, SS310, Inconel 600/800, HRS 446, Hastalloy, Monel, etc.

Configuration: Simplex / Duplex / Others

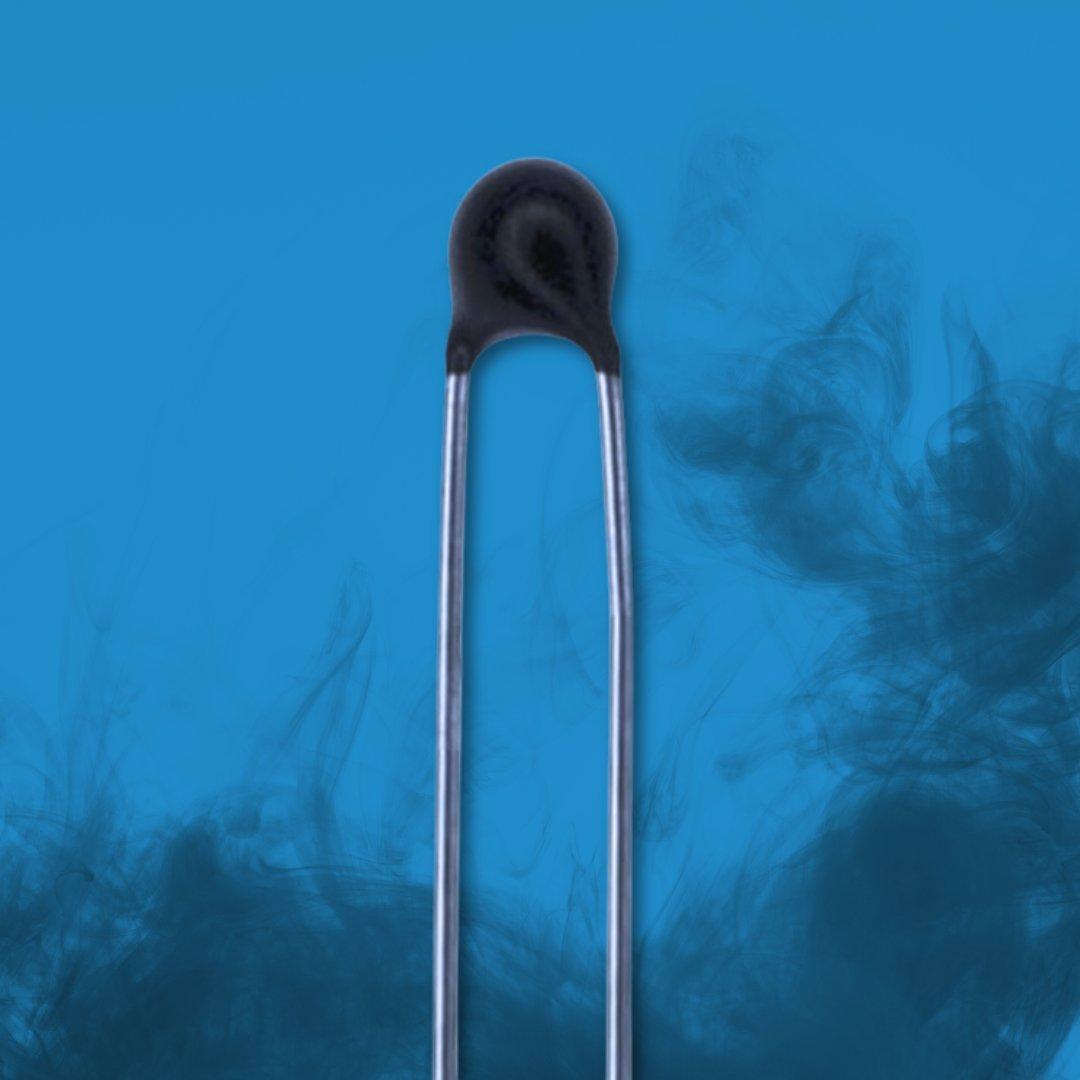

A thermistor is a type of temperature-sensing device that changes its electrical resistance in response to temperature variations. Made from semiconductor materials, thermistors provide accurate and rapid temperature detection for a wide range of applications.

Types of Thermistors:

Applications:

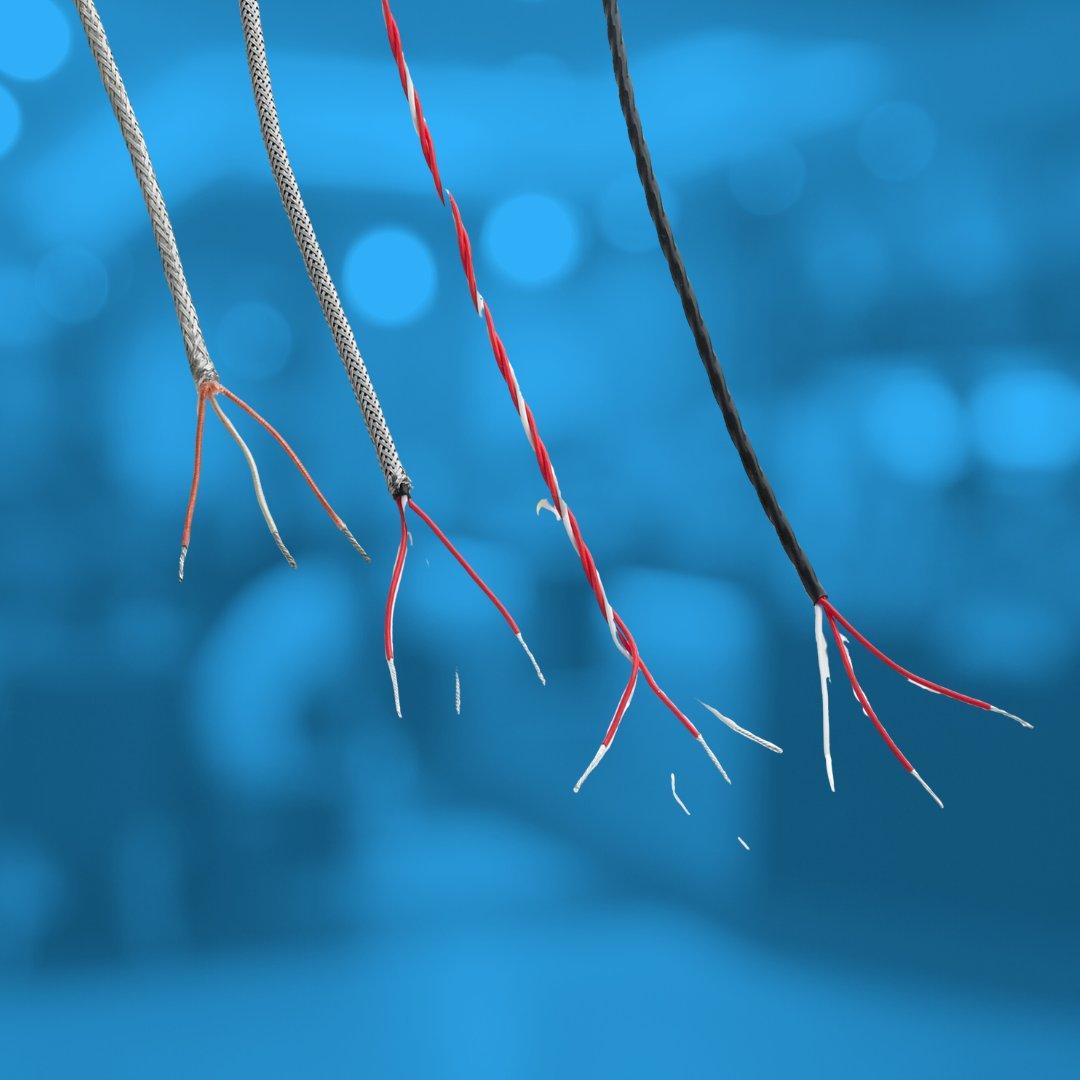

Thermocouple and RTD (Resistance Temperature Detector) cables are specialized cables designed to connect temperature sensors to measurement instruments or control systems. Proper selection ensures accurate, reliable temperature data transmission in various industrial environments.

Thermocouple Cables:

RTD (Resistance Temperature Detector) cables are designed to connect RTD sensors to measurement and control systems with minimal signal loss and maximum accuracy. These cables are essential for ensuring reliable temperature readings in industrial and laboratory environments.

Considerations:

When selecting Thermocouple and RTD cables, always refer to manufacturer specifications and consider temperature range, accuracy requirements, environmental conditions, and cable length to ensure reliable and accurate temperature measurements.

A Bearing RTD is a temperature-sensing device designed to monitor bearing temperatures in rotating machinery such as motors, pumps, turbines, and gearboxes. Accurate temperature monitoring helps prevent overheating, reduces wear, and extends equipment life.

Types of Bearing RTDs:

Key Specifications:

Stator slot winding RTDs are designed to fit into the slots between stator windings to monitor temperature rise and prevent overheating. The sensing element extends along most of the body length, allowing for an average temperature reading that can detect hot spots missed by conventional sensors.

These RTDs can also be used in various other applications where average temperature measurement is required. Custom designs are available to meet specific dimensional and performance requirements.

A Sanitary RTD is a temperature-sensing device designed for hygienic and sterile applications where cleanliness and precision are essential. It operates effectively in a wide temperature range of -195°C to +650°C.

These sensors are built with stainless steel housings and polished sanitary fittings to comply with hygiene standards and prevent bacterial contamination. Sanitary RTDs are commonly used in industries such as:

An Autoclave Sensor is a precision temperature-sensing device designed to monitor temperature, pressure, and sterilization parameters inside an autoclave chamber. These sensors ensure accurate and reliable sterilization cycles with Class Accuracy.

Common applications include:

Temperature sensor calibration ensures accurate and reliable temperature measurements. The process involves comparing a sensor’s readings with a known reference standard and adjusting for any deviation.

A Temperature Controller is an electronic device designed to regulate and maintain a specific temperature set point automatically. It ensures process stability and precision across industrial and laboratory environments.

By using a Temperature Controller, you can maintain precise temperature control, optimize operational efficiency, and ensure safety in various applications.

A Temperature Indicator is an instrument designed to display the current temperature reading, typically used alongside a temperature sensor or thermocouple to provide an accurate and real-time visual representation of temperature levels.

By using a Temperature Indicator, you can easily monitor and track temperature variations, ensuring optimal performance and safety across industrial, laboratory, and environmental applications.

A Temperature Transmitter is an electronic device that converts a temperature signal from a sensor or thermocouple into a standardized output signal such as 4–20 mA or 0–10 V. It enables reliable signal transmission to control systems, recorders, or display units for accurate temperature monitoring and process control.

By using a Temperature Transmitter, you can ensure accurate, stable, and efficient temperature signal transmission for industrial, laboratory, and process automation systems.

A Pressure Transmitter is a precision device that converts applied pressure into an electrical signal—typically 4–20 mA or digital output. It provides accurate and stable pressure measurement across various industrial and commercial applications.

Pressure Transmitters are essential in modern automation, ensuring reliable monitoring and control of pressure variables in critical processes.

A Heater Coil consists of a coil of resistance wire—commonly made from nickel-chromium (nichrome) or iron-chromium-aluminium alloy—that converts electrical energy into heat. These coils are used across various industrial and domestic heating applications due to their high resistivity, durability, and thermal efficiency.

Heater Coils are essential in applications such as furnaces, ovens, dryers, water heaters, and process heating systems, offering efficient and reliable heat generation.

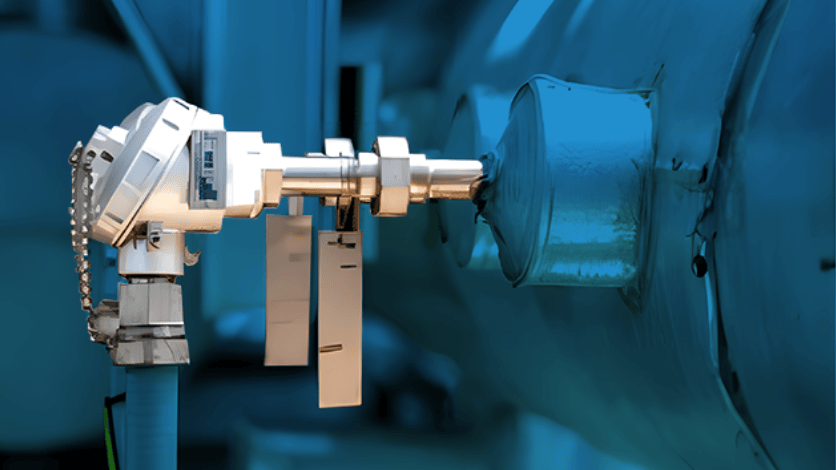

We manufacture fasteners, flanges, and thermowells.

Adapter, Adjustable compression fitting (BSP, NPT, ISO Metric)

Material: Stainless Steel, Copper, Nickel

Blind Flange, Slip-on Flange, Socket Weld Flange, Weld Neck Flange, Threaded Flange

Material: Stainless Steel, Carbon Steel, Inconel, Other Sizes on request

Material: Stainless Steel, Carbon Steel, Alloy 825/625, Inconel, Other Sizes on request

STD: PTC193TW-Thermowells

Pressure gauges are available in dial sizes of 63, 100, 150 & 250mm and cover ranges from 6 mbar up to 4000 bar with accuracy from 1.6% to 1% of f.s. Wetted parts include SS316/316L, Monel, Hastelloy, and Inconel.

Diaphragm seals are available with flanged, threaded, sanitary, and other connections. Wetted parts are available in SS316/316L, Monel, Hastelloy, Inconel, Tantalum, Titanium, Nickel, Alloy 20, Teflon, PVC, and more.

Filling fluids include Silicone, Syltherm 800, Halocarbon, and Food Grade Oil. Diaphragm seals are suitable for pressure and differential pressure gauges, switches, and transmitters. Standard process connections vary from 1/4" NB to 4" NB (Class 150# to 2500#).

Differential pressure gauges are available in dial sizes of 63, 100, 115, and 150mm. Sensing elements include single or double diaphragms, bellows, and magnetic pistons. These gauges can measure ranges from 1 mbar to 25 bar with an accuracy of 2.5% to 1% and a static pressure rating of up to 400 bar.

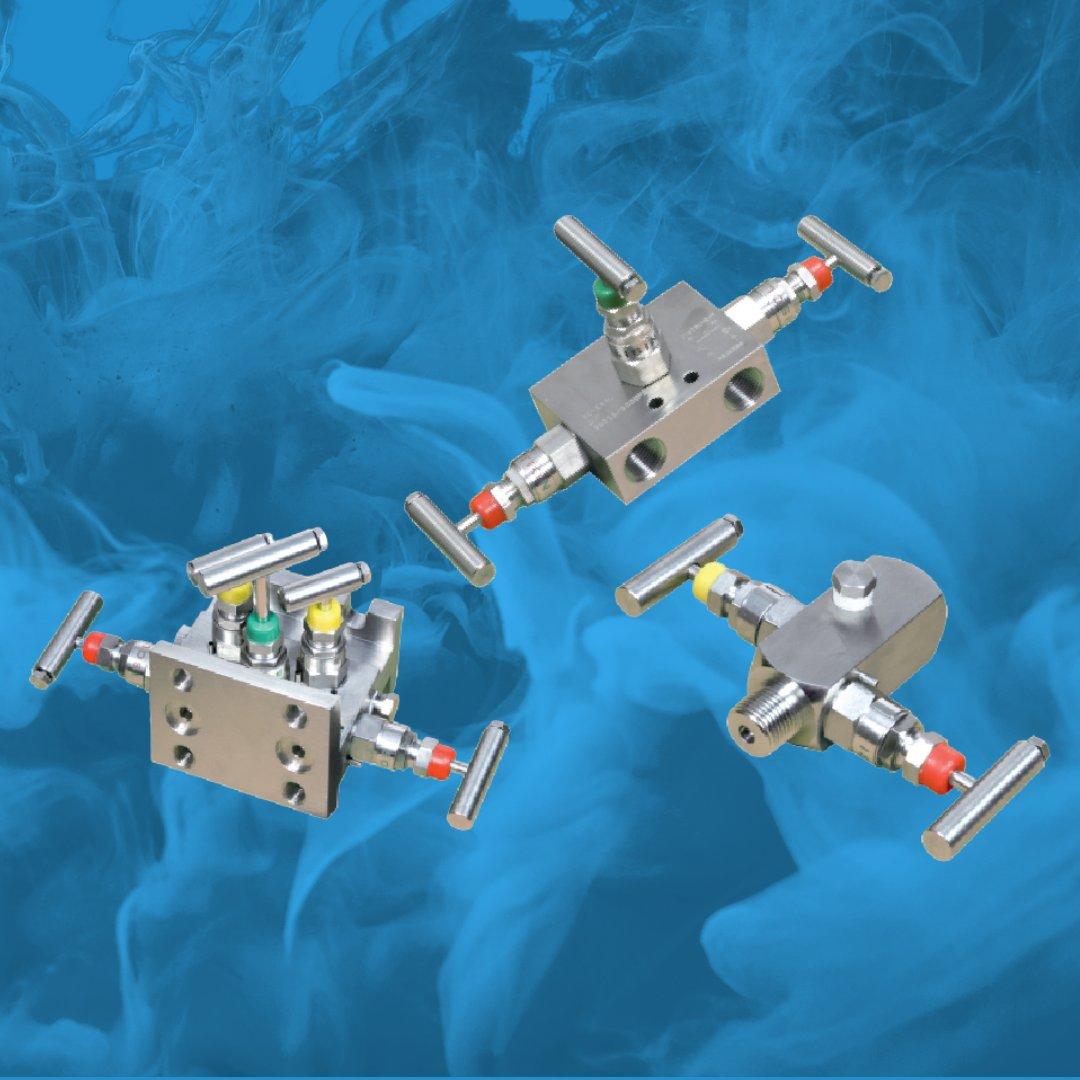

We manufacture needle valves up to 10,000 psi rating and 2-valve, 3-valve, and 5-valve manifolds of direct mounting type, T-type, and H-type coplanar type. These are available in SS316/316L, Monel, Inconel, Hastelloy, Duplex, and other materials with NACE certification.

Digital pressure gauges are available with accuracy from 0.25% to 0.025% f.s. and ranges from vacuum to 5000 bar. Pressure calibrators come with intrinsic safety certification for use in hazardous areas. Dead weight testers are available with ranges up to 2000 bar and uncertainty of ±0.008% of reading.

We manufacture accessories such as snubbers, gauge savers, syphons, needle valves, gauge cocks, cooling towers, and manifolds for pressure instruments. These are available in materials like SS316/316L, duplex, Hastelloy, Monel, and other materials with NACE certification.

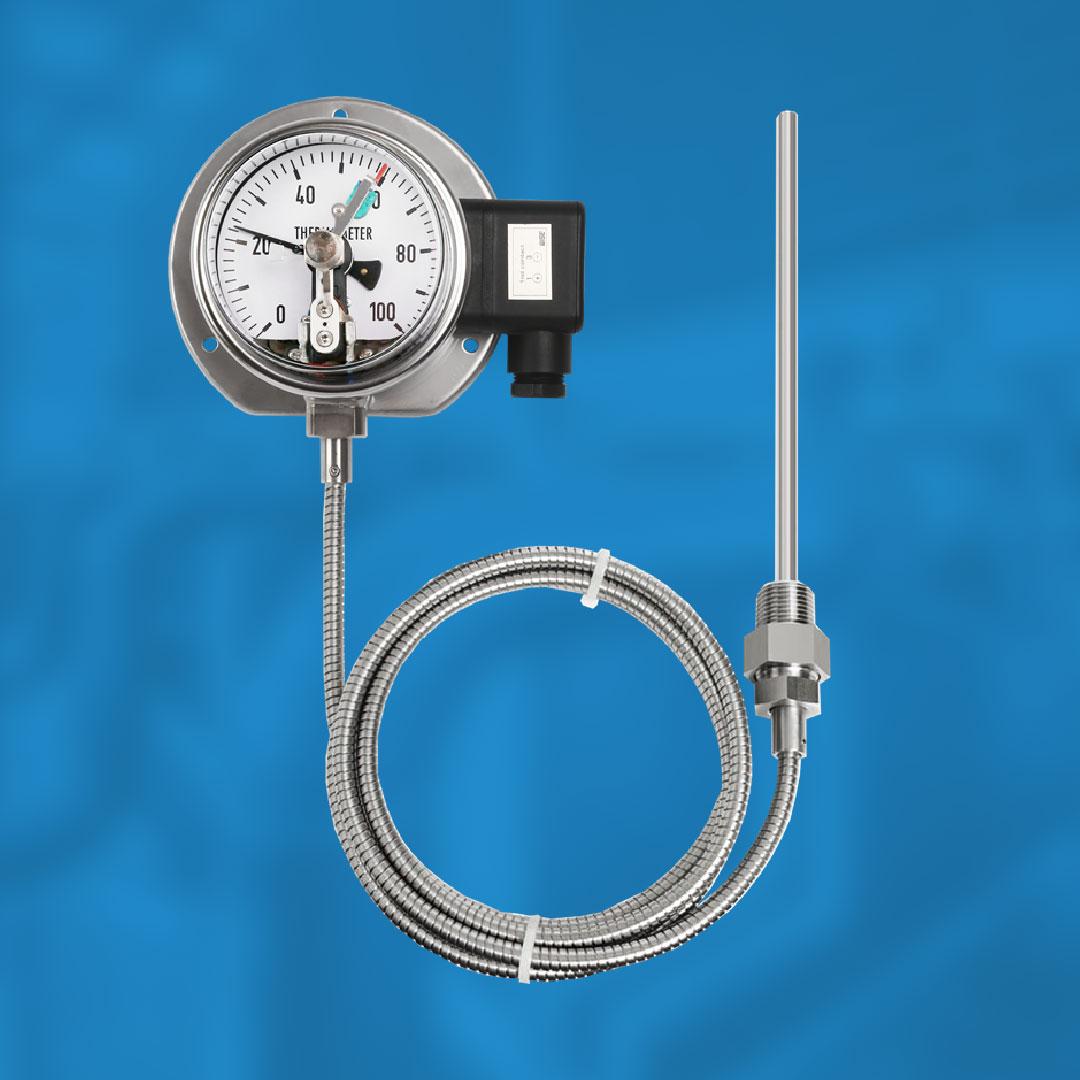

A temperature gauge is a device used to measure and display temperature readings. Common types include Bimetallic and Gas Filled.